Use Of Inspection Chambers

Inspection Chambers are a crucial part of any drainage system as they allow for testing, inspection and cleaning of the system. The key point to remember is that every point on any drainage system should be accessible from an inspection chamber or a rodding eye.

A chamber should be used whenever there is a change of direction of more than 30 degrees and whenever two pipes come together in a junction of more than 45 degrees. No point on the system should be further than 22m away from an inspection chamber, even on a straight run of pipe.

Inspection chamber size requirement

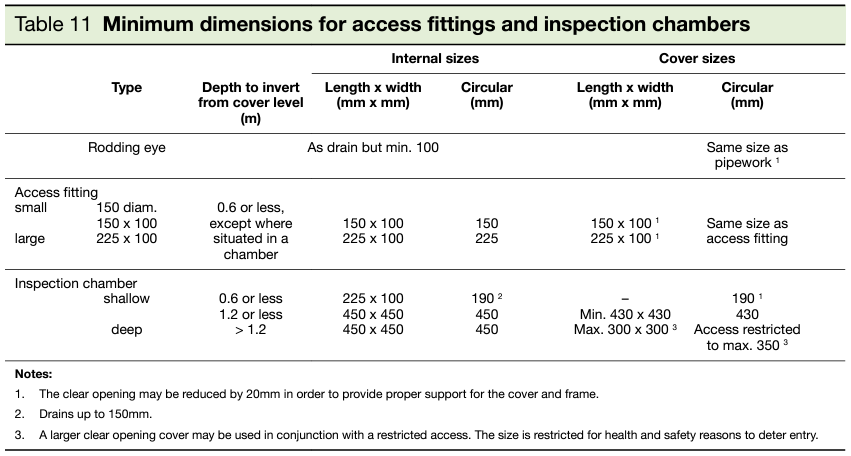

Below is a table from Building Regulations 2010 - Drainage and Waste Disposal published by the UK government regarding the minimum dimensions required for access fittings and inspection chambers:

Our mini access chambers can be used to an invert depth of 600mm (the distance from cover level to the inside of the bottom of the pipe).

Our 450mm chamber can be used to an invert depth of 1200mm when used with a standard 450mm cover, or 3000mm when used with a restricted access cover.

Side risers are used to increase the height of the inspection chamber. These risers can be cut down at indicated points to give a more accurate height. Covers and frames should be adjusted to the finished ground level and placed set of a bed of concrete of at least 50mm in depth.

Side branches of inspection chambers should not be used to change direction of the main flow, as a self cleansing flow through the chamber cannot be guaranteed. Should a change of direction be required,single socket bend should be sited at the point of entry to the chamber.

Inspection chambers should be installed on a suitable bed dependent upon the quality of the trench and the backfill materials.

How close can you build to an inspection chamber?

When undertaking construction on a previously developed site or adding to an existing property, it's crucial to avoid obstructing existing and operational inspection chambers.

These chambers need to remain accessible for local authorities to conduct necessary surveys and perform maintenance and repairs. To ensure proper access, all new foundation constructions must maintain a minimum clearance of 0.5 metres from any existing inspection chamber or manhole structure.

If the intended foundations fall within this restricted area, you have two options: you can either redesign the extension or addition to avoid the specified region, or you can coordinate the repositioning of the inspection chamber and drains simultaneously with the excavation of the foundations.

When do I need to apply for a build-over agreement?

When constructing an extension or new addition, you may need to request a build-over agreement from the relevant local authority. This is essential when constructing within 3.0 metres of a public sewer (serving multiple properties) or within 1.0 metre of the point where your private drain (solely serving your property) crosses the property boundary to become a public lateral drain.

The size of the drain near or under your construction site will also impact the application process for a build-over agreement. If the domestic sewer is 160mm or less in diameter, you might qualify for a self-certified build-over agreement. This is a cost-free, online procedure that allows you to confirm compliance with all necessary requirements.

However, for larger diameter sewers, or if you don't meet the criteria for a self-certified agreement, you will be required to apply to the water authority for an approved build-over agreement, which will involve a set fee.