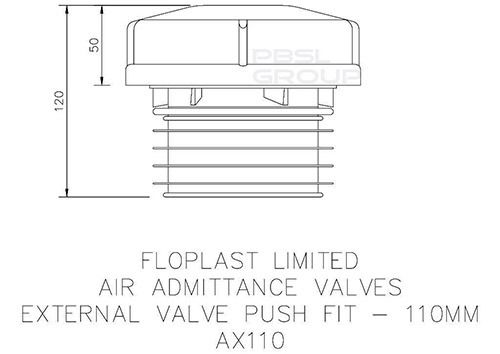

FloPlast Air Admittance Valve External - 110mm Black

| Code | AX110B |

|---|

Air admittance valves are an ingeniously designed fitting that avoids the need for a soil vent pipe to terminate externally and within the strict traditional guidelines that govern position.

Traditionally, open vent pipes needed to be installed at least 900mm above any opening into the building that is within 3 metres of the vent pipe. This was to prevent foul odours from entering the living space. The beauty of air admittance valves is that they allow air to be drawn into the pipework to prevent pressure build up, but crucially no foul odours can escape from the system.

This means that an air admittance valve can now be situated anywhere in the above ground drainage system provided it is at least 200mm above the highest wet entry point of the soil vent pipe (the wet entry point is the highest point of the soil pipe system that waste water can flow into).

There are two types of air admittance valves – internal and external. Both should always be fitted in an upright position. External air valves incorporate a push fit rubber seal connection into the soil pipe. Internal air valves are a simple push fit around the outside of the soil pipe. Both types can also be used as a secondary rodding point.

Also often referred to as Durgo Valves, air admittance valves enable installers to save on both labour and material costs. They are also far safer than open vent pipes from a maintenance perspective as they remove the need to gain access above roof level.